Step-by-Step Guide to Calculating Takt Time in Six Sigma

By Mindcypress

Takt time is a fundamental concept in Lean and Six Sigma that one learns during their Six Sigma Certification course. It is one of the most important terms you learn among other six sigma definitions. It serves as an important metric for optimizing production processes and meeting customer demand. Organizations understand and calculate the Takt time to streamline operations and improve efficiency. It also helps them achieve greater alignment between production capacity and customer requirements. In this comprehensive guide, we will dig into the principles and formulas behind Takt time calculation. Further, we will provide a step-by-step approach to help organizations implement this essential Lean tool effectively.

What is Takt time in Six Sigma?

Takt time, which helps in lean six sigma process improvement, is derived from the "Takt," a German word. It means rhythm or beat. It represents the maximum allowable time for completing a task or producing a unit to meet customer demand while maintaining a steady production flow. Takt time is calculated based on customer demand (demand rate) and available production time, providing a framework for balancing workload and optimizing production efficiency.

Step-by-Step Guide to Calculating Takt time

Determine Customer Demand

The first step in calculating Takt time is to determine the customer demand or demand rate. This involves analyzing historical sales data, market forecasts, customer orders, and other relevant information to quantify the number of units or services required within a specific time period, such as a day, week, or month.

Define Available Production Time

Next, identify the total available production time within the same time period considered for customer demand. This includes accounting for factors such as shift schedules, breaks, downtime, and planned maintenance activities that may impact production capacity.

Calculate Takt Time in Six Sigma

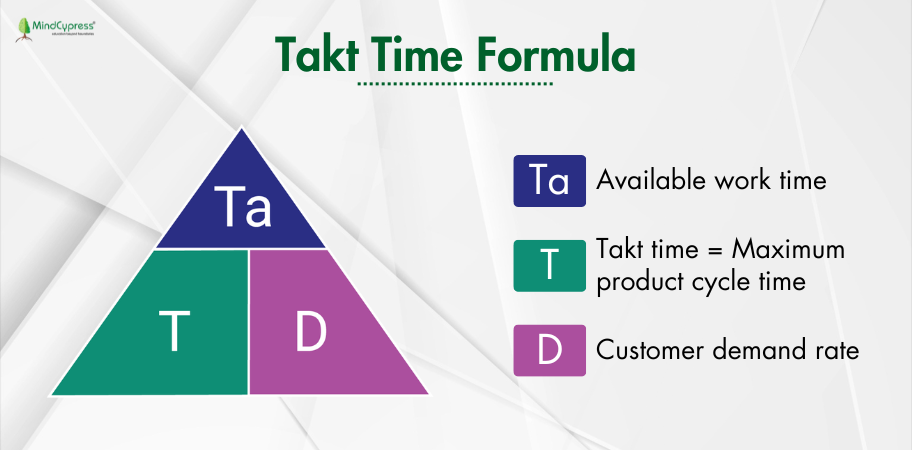

Once you have determined the customer demand and available production time, you can calculate Takt time using the following formula:

Takt Time = Available Production Time / Customer Demand

Interpret and Validate Results

The calculated Takt time represents the target cycle time or pace at which units or services should be produced to meet customer demand efficiently. It serves as a reference point for aligning production activities, scheduling resources, and balancing workload across production processes.

Monitor and Adjust

Takt time is not a static metric and may fluctuate based on changes in customer demand, production capacity, or process efficiency. It is essential to monitor Takt time regularly and make adjustments as needed to maintain optimal production flow and meet evolving customer requirements.

Principles and Formulas

Takt time calculation is based on the principle of synchronizing production with customer demand to achieve a balanced and efficient workflow. The formula for calculating Takt time is straightforward, emphasizing the importance of aligning production capacity with customer requirements to avoid overproduction or underproduction.

Conclusion: Takt Time in Six Sigma

In conclusion, Takt time calculation is a critical tool for lean six sigma process improvement. It helps organizations in optimizing production processes, improve efficiency, and enhance customer satisfaction. By following the step-by-step guide outlined in this blog, organizations can calculate Takt time accurately and leverage it as a strategic framework for driving continuous improvement and operational excellence. Organizations can achieve greater agility, responsiveness, and competitiveness by understanding Takt time principles and formulas.

Do you wish to learn more about Takt time and other important six sigma definitions and their applications, enroll at MindCypress. It is a learning partner for thousands of professionals and non-professionals who want to advance their career. The organization offers Six Sigma Certification to all those who want to step into the project and quality management field. The certification helps unlock several interesting opportunities for learners and cater to their career growth requirements.