Common Cause Variation vs. Special Cause Variation: Key Differences

By Mindcypress

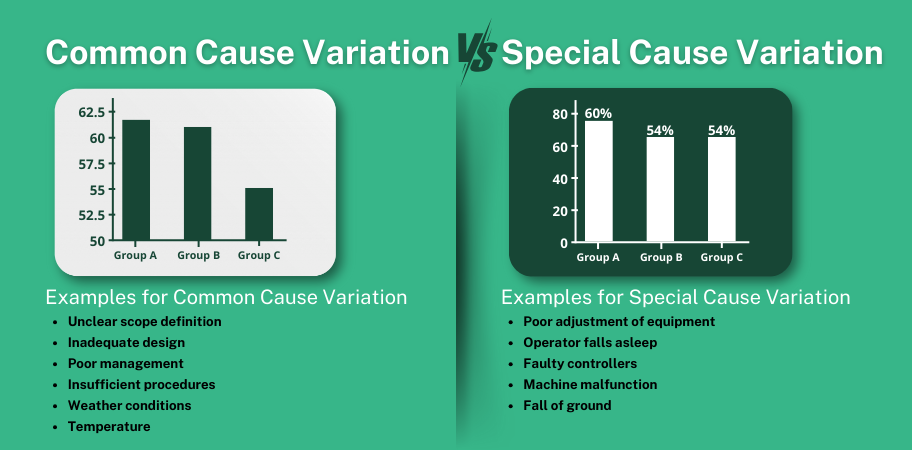

It is quite essential to understand variation pertaining to process involvement and quality management, for achieving organizational success. Variations are of two types: Common Cause variation and Special Cause Variation.

Both types play a significant role that helps determine the stability and performance of processes.

In this blog, we will explain the key differences between the two types of variation with the help of real-world examples for a better understanding.

Common Cause Variation

Common cause variation is innate and a natural part of any process and its operation. It depicts normal fluctuations that occur over time due to factors innate in the process itself. The process operates within certain statistical limits under normal conditions. Hence, it is stable and predictable.

Examples:

- Daily fluctuations in call volumes at a customer service center

- Minor variations in product dimensions during manufacturing

- Variability in delivery times for routine shipments

Special Cause Variation

Special cause variation is caused by an external factor. It is not innate in the process and leads to outcomes that are unpredictable and uncommon. Special cause variation can lead to striking deviations as opposed to expected and stable outcomes.

Examples:

- Machine breakdowns leading to production delays.

- Employee errors resulting in quality defects.

- Supplier issues causing disruptions in the supply chain.

Key Differences

Nature

- It is innate and a natural part of any process and its operation with natural fluctuations

- Special cause variation is caused by an external factor. It is not innate in the process.

Predictability

- Common cause variation is predictable and stable, operating within certain statistical limits.

- Special cause variation is unpredictable and can result in significant deviations from the expected performance of the process.

Management Approach

- Common cause variation requires process improvements and adjustments to reduce variability and enhance stability over time.

- Special cause variation requires immediate investigation and corrective action to address the root cause and prevent recurrence.

Conclusion

In summary, there are two different types of variation that affect the stability and performance of processes. Special cause variation arises from outside influences that have unanticipated effects, whereas the other variation reflects intrinsic natural oscillations in the process. Organizations can optimize process performance, improve quality, and promote continuous improvement by utilizing suitable management practices and comprehending the fundamental distinctions between various types of variation.

Are you looking for an opportunity to learn more about quality management? MindCypress offers Lean Six Sigma Green Belt certification training and Lean Six Sigma Black Belt certification through live online training. The online training equips learners with the necessary knowledge and skills to start their careers in their desired fields.