8D Problem Solving Concepts with Lean Six Sigma

Are you trying to find an organized solution to persistent issues in your company that you can't seem to shake off? Your answer is the 8D Problem-Solving model. Rooted in the principles of Lean Six Sigma, the 8D methodology offers a structured and systematic approach to identify, analyze, and resolve complex problems. It is a very useful tool for situations where anything goes wrong or requires change. It's a deliberate, cooperative way to solve important issues to improve production procedures. It accomplishes this through assisting with root cause investigation, containment plan creation, and the application of remedial solutions.

Let's understand it more thoroughly!

8D Problem Solving: What Is It?

8D problem solving is a useful strategy for dealing with challenging situations at the workplace. The term "eight disciplines," or "8D," refers to a defined framework that project teams can work within. Organizations can address extremely difficult or crucial operational challenges by implementing the analysis and procedures it offers.

During World War II, the US military first employed this variant. The "Team Oriented Problem Solving" (TOPS) approach was its name, and Ford Motors later made it well-known. The car maker improved the procedure and equipment, renaming it as the Eight Disciplines (8D) of Problem Solving. 8D can be useful in Kaizen continuous improvement efforts and striving towards lean processes.

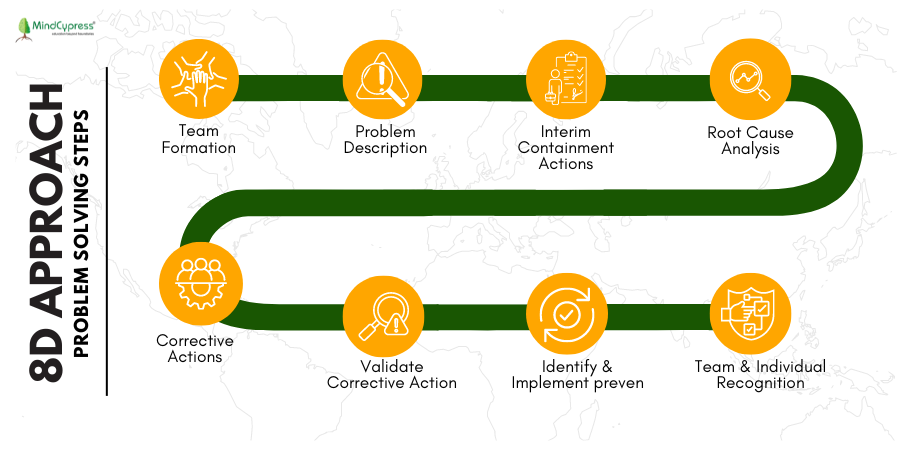

Understanding the 8D Problem Solving Methodology

Organizations utilize the 8D Problem Solving methodology as a methodical strategy to examine and resolve recurrent issues, flaws, or departures from intended results. Each discipline specializes in a particular area of quality improvement and problem-solving, comprising eight disciplines in total. These are the Eight Disciplines:

D1: Establish the Team:

Putting together a cross-functional team of people with a range of perspectives, abilities, and knowledge pertinent to the issue at hand is the first step in the 8D process. The team leader, who is frequently a certified Six Sigma specialist, is essential in directing the team's problem-solving activities and encouraging cooperation among members.

D2: Describe the Problem:

The next discipline is defining the issue or departure from expected performance in detail when the team is formed. In order to complete this phase, you must collect pertinent data, carry out a root cause analysis, and record the problem's symptoms, extent, and effects on stakeholders, procedures, and results.

D3: Implement Interim Containment Actions:

Interim containment measures are taken to reduce the problem's immediate impact and stop it from getting worse. These stopgap solutions are intended to maintain order, prevent further damage to consumers, processes, and resources, and stop the spread of faults or problems.

D4: Identify Root Causes:

In this discipline, the team carries out a comprehensive analysis to determine the fundamental issues that are causing the issue. Through data analysis and testing, techniques including cause-and-effect diagrams, fishbone diagrams, and 5 Whys analysis are frequently used to prioritize root reasons, investigate probable causes, and validate hypotheses.

D5: Develop Permanent Corrective Actions:

In order to address the root causes found, the team develops and puts into effect long-term corrective measures based on the results of the root cause analysis. These steps are intended to address the underlying causes of the issue, avoid a recurrence, and enhance the overall dependability and performance of the process.

D6: Verify Corrective Actions:

The team tests, monitors, and validates the remedial actions after they are put into place to ensure they are working. In this step, information is gathered, KPIs are measured, and the effects of the corrective measures on process efficiency and customer satisfaction are evaluated.

D7: Prevent Recurrence:

In order to maintain long-term sustainability and stop the issue from happening again, proactive steps are done to fix systemic problems, enhance procedures, and strengthen resistance to future deviations. This could entail introducing preventative maintenance measures, educating staff, putting in place new controls, and revising procedures.

D8: Recognize Team Effort:

Honoring and applauding the work of the problem-solving team is the last discipline in the 8D Problem Solving process. In an organization, sharing lessons learned, recording best practices, and recognizing the achievements of team members fosters a culture of innovation and continuous improvement.

Applications of the 8D Problem Solving Methodology:

The 8D Problem Solving methodology has broad applications in a number of different sectors and industries, such as the automotive, aerospace, healthcare, and manufacturing industries. Companies use the 8D process to handle problems related to process deviations, customer complaints, safety incidents, and other issues that affect customer happiness, product quality, and organizational performance.

By adopting the 8D Problem Solving methodology, organizations can:

- Improve product and service quality

- Enhance customer satisfaction and loyalty

- Reduce defects, waste, and rework

- Increase process efficiency and reliability

- Foster a culture of continuous improvement and innovation

- Strengthen cross-functional collaboration and problem-solving capabilities

- Drive cost savings and competitive advantage in the marketplace

Integrating 8D Problem Solving Methodology with Lean Six Sigma

Here's how the 8D methodology can be effectively integrated with Lean Six Sigma:

Define the Problem:

The Define phase of Lean Six Sigma concentrates on precisely describing the problem description and project objectives. Similar to this, the 8D methodology's initial step is to describe the problem, making sure that everyone involved has an equal grasp of the matter at hand.

Establish a Cross-Functional Team:

The 8D technique and Lean Six Sigma both stress how crucial it is to put together a cross-functional team with a range of backgrounds and specialties. This group approaches the issue cooperatively, using their combined expertise to generate practical answers.

Use Data-Driven Analysis:

Data-driven analysis is a key component of Lean Six Sigma, which uses it to analyze process performance and pinpoint the sources of issues. In a similar vein, the 8D methodology places a strong emphasis on using data and statistical tools to examine the issue and pinpoint its causes.

Apply Root Cause Analysis:

A fundamental element of both the 8D technique and Lean Six Sigma is root cause analysis. Organizations are able to address the core of an issue rather than just its symptoms and adopt more focused and long-lasting solutions by determining the underlying causes of problems.

Implement Corrective Actions:

Find the underlying reasons for the issue and then put corrective measures in place to stop it from happening again. Lean Six Sigma offers an organized method for putting these solutions into practice and making sure they are long-lasting and successful.

Monitor and Control:

Measures are implemented to monitor process performance and guarantee that improvements are maintained throughout the Control phase of Lean Six Sigma. In a similar vein, the 8D technique incorporates guidelines for keeping an eye on the success of remedial efforts and putting preventative measures in place to steer clear of problems down the road.

Continuous Improvement:

Lean Six Sigma and the 8D technique both encourage a business to adopt a continuous improvement culture in which waste, errors, and inefficiencies are continuously sought out and eliminated. Organizations can promote continuous innovation and improvement throughout their operations by combining these two approaches.

All things considered, the combination of Lean Six Sigma and the 8D problem-solving methodology gives organizations a strong framework. It enables to handle challenging issues, promoting long-term improvement, and attaining operational excellence. Organizations can reduce waste and defects, improve customer value, and streamline their problem-solving processes by utilizing the strengths of each methodology.

Conclusion:

To sum up, the 8D Problem Solving methodology provides a methodical and organized way to tackle intricate issues. It promotes ongoing development within companies. Teams can improve quality, efficiency, and customer satisfaction by implementing effective corrective actions, preventing recurrence of errors, and rigorously identifying root causes by adhering to the Eight Disciplines framework. In today's ever-changing business environment, organizations aim to pursue operational excellence and competitive advantage for greater success. It makes the 8D Problem Solving technique an essential skill to have.

Stepping into the world of project or quality management? MindCypress offers one of the top lean six sigma certification courses to professionals and non-professionals alike. The six sigma classes are based online with industry experts as trainers; who understand the concepts of six sigma thoroughly.